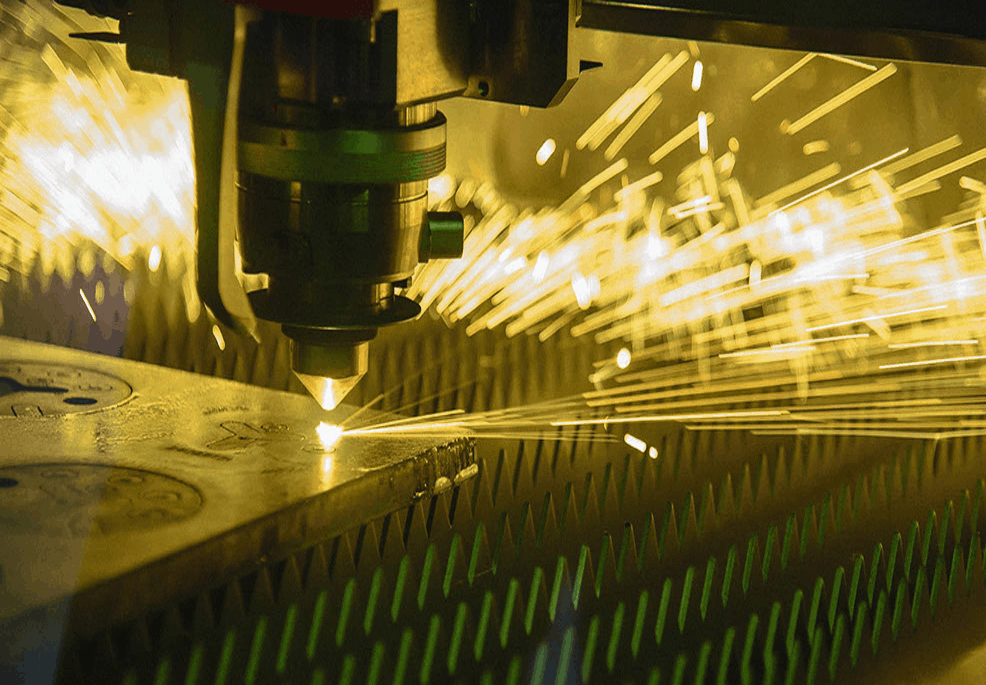

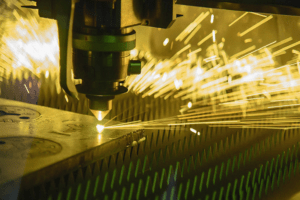

Fiber laser cutting incorporates state-of-the-art fiber optic technology and banks of diodes to produce powerful lasers capable of cutting a wide variety of materials with exceptional precision.

At South Shore Manufacturing, we use a cutting-edge 2kW fiber laser to create detailed, complex, and precise components from a wide range of materials. Our adaptable and versatile high-speed laser head uses a flying optic configuration that enhances our ability to cut everything from thin sheets of metal to thick, heavy plates with an exceptional degree of accuracy and repeatability.

How Does a Fiber Laser Work?

Fiber-optic laser cutting is a relatively new technology. It uses a bank of diodes and fiber cables to amplify a laser beam. The strengthened laser beam is focused through a lens, which directs the beam based on the specifications entered into the computerized control system.

With South Shore’s fiber optic laser cutter, we can cut precision components from prototype to high-volume production runs with a degree of efficiency unmatched by traditional CO2 laser cutting processes. Fiber laser cutters provide a higher degree of speed and accuracy than CO2 lasers while using less energy, saving our customers both time and money.

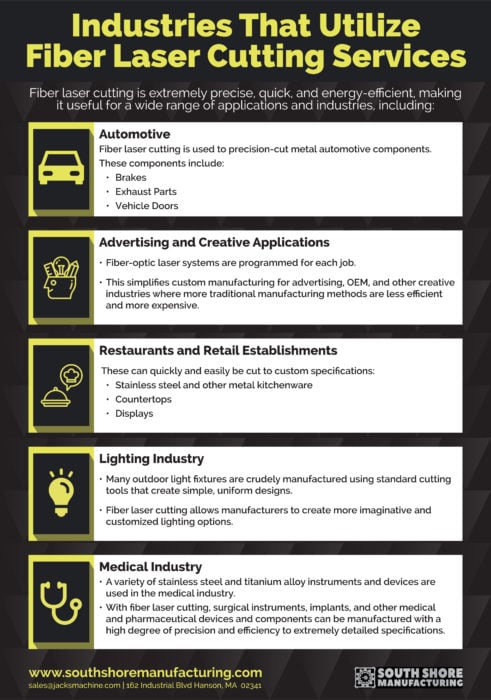

Industries that Utilize Fiber Laser Cutting Services

Fiber laser cutting is extremely precise, quick, and energy-efficient, making it useful for a wide range of applications and industries, including:

- Automotive Industry. Fiber laser cutting is used to precision-cut metal automotive components, including brakes, exhaust parts, and vehicle doors.

- Advertising and Creative Applications. Fiber-optic laser systems are programmed for each job, which simplifies custom manufacturing for advertising, OEM, and other creative industries where more traditional manufacturing methods are less efficient and more expensive.

- Restaurants and Retail Establishments. Stainless steel and other metal kitchenware, countertops, and displays can quickly and easily be cut to custom specifications using fiber laser cutting services.

- Lighting Industry. Many outdoor light fixtures are crudely manufactured using standard cutting tools that create simple, uniform designs. Fiber laser cutting allows manufacturers to create more imaginative and customized lighting options.

- Medical Industry. A variety of stainless steel and titanium alloy instruments and devices are used in the medical industry. With fiber laser cutting, surgical instruments, implants, and other medical and pharmaceutical devices and components can be manufactured with a high degree of precision and efficiency to extremely detailed specifications.

Fiber Laser Cutting Advantages & Capabilities

Fiber laser cutting is a versatile process that offers a variety of unique advantages over other manufacturing methods. Some primary benefits of using fiber-optic lasers include:

- Enhanced manufacturing speed and efficiency

- Lower power consumption

- Reduced operating costs

- Extremely flexible design options

- High material versatility

- Minimal grinding and finishing necessary

- Quick and easy setup

General Capabilities

At South Shore Manufacturing, we offer the following fiber laser cutting capabilities:

- Contract manufacturing

- Full production fabrication

- Prototyping and sampling

Specifications

Fiber optic lasers offer exceptional precision with extremely tight tolerances. At South Shore Manufacturing, we offer fiber laser cutting services with the following specifications:

- Maximum Thickness: 3/8″

- Maximum Cutting Size: 48.0″ x 48.0″

- Tolerance: (±) 0.001″

- Power Rating: 2kW

- Kerf: 0.003″

Materials

Fiber laser cutting can be used on an extremely wide range of materials, even exceptionally hard specialty alloys. We offer a wide range of material options to suit the needs of various applications. These materials include:

- Aluminum

- Stainless Steel

- Inconel®

- Monel®

- Ferrous Metal

- Heavy Plate

- Non-Ferrous Metal

- Steel

- Thin Metal

Fiber Laser Cutting Services from South Shore Manufacturing

At South Shore Manufacturing, we pride ourselves on providing our customers in every industry with the highest quality laser cut components and products. Using the latest fiber optic laser technology, we are capable of producing detailed custom-designed components quickly and efficiently. With more than 30 years of experience, we have the knowledge and expertise necessary to manufacture even your most technical and detailed products. To learn more about our fiber laser cutting services, contact our experts today or request a quote.